Designed to meet your precise requirements. The possibilities are endless.

Morito Scovill Americas precision stamping capabilities provide full service product and tooling design. A staff of industrial engineers, skilled tool makers and setters and quality control technicians are committed to meeting specific customer needs.

• Customized stamping of metal alloys such as brass, stainless and carbon steel as well as aluminum

• Up to 60 ton stamping and multi row tool capability

• Transfer and progressive presses allow for various quantity options

• Statistical process control

• Sub assembly capabilities

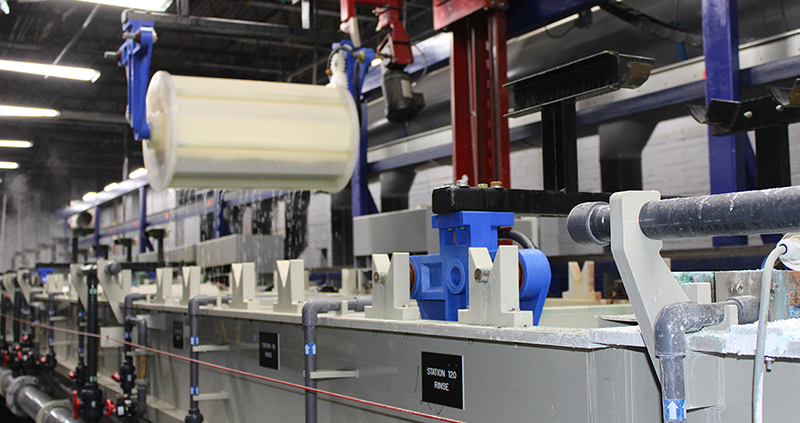

In-house plating and coating capabilities offer solutions to multiple finishing needs to protect metal components from environmental factors like heat or corrosion. Processes are strictly inspected and performed in accordance to required specifications.

• Nickel plating utilizing state-of-the-art barrel plater

• Finishing options include black oxide coating and wet paint

• In-house CMI to certify plating thicknesses

State-of-the-art auto-bagging system accommodates small part product packaging productivity. 100% automated, hands free and capable of feeding exact quantities through 4 separate bowl feeds.

• Small order fulfillment to ecommerce packaging

• Bag thicknesses up to 10 mil

• Heat sealed for safe and secure packaging

• Custom labeling option

With hundreds of textile and attachment options at our fingertips, the product design specialists at Morito Scovill Americas stand ready to transform ideas and concepts into prototypes and samples that are efficiently developed to meet critical production time lines.

Utilizing our exceptional design, engineering, manufacturing and quality teams, MSA provides customer-centered solutions that allow us to build to your unique specifications.

Discuss your next project with one of our experts today.